KOREAN TIME

Monday~Fridays 09:30~18:00

Monday~Fridays 09:30~18:00

-Saw blade’s movement back and forth also can be finely regulated.

-With the digital scale attached in the machine, user can do fine/precise work.

-Timer : With this, the machine can pause during the work.

item | specification |

|---|---|

Voltage | 3P 380V

|

Frequency | 50 ~ 60Hz |

Power Consumption | 7.5Kw |

Circular Saw Blade | Ø300mm |

Maximum Cutting Capability | : 2500mm x 1280mm x 50mm (thickness)

RPM : 4200 |

Size | (L x W x H) 3550mm x 2300mm x 1660mm 3550mm x 2980mm(secondary table) x 1660mm |

Weight | Approx. 1500Kg |

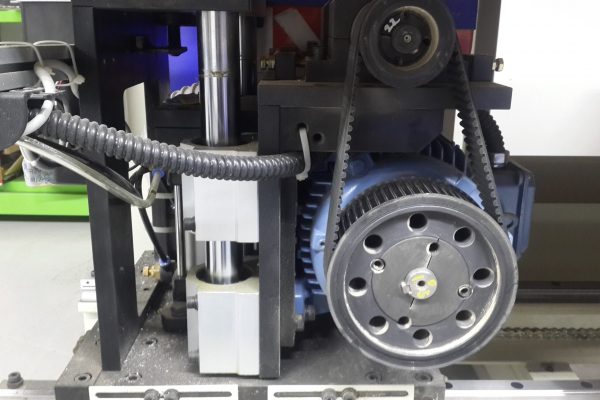

Main Axis Motor

► For the saw blade power transmission, it applies timing belt and gear

► Even for cutting thick panel, there’s no-load-operation on the saw blade

Main Axis Movement

► At LM guide stands for main movement, it applies train railroad. Train railroad is welded and precisely processed that guarantees its stable movement for a long time.

Built-in Dust Collector and box

► Other conventional cutting machines’ dust collectors are located at outer that requires extra space for it.

► However, BM2’s dust collector is located at inside of the machinery that doesn’t require extra space for it.

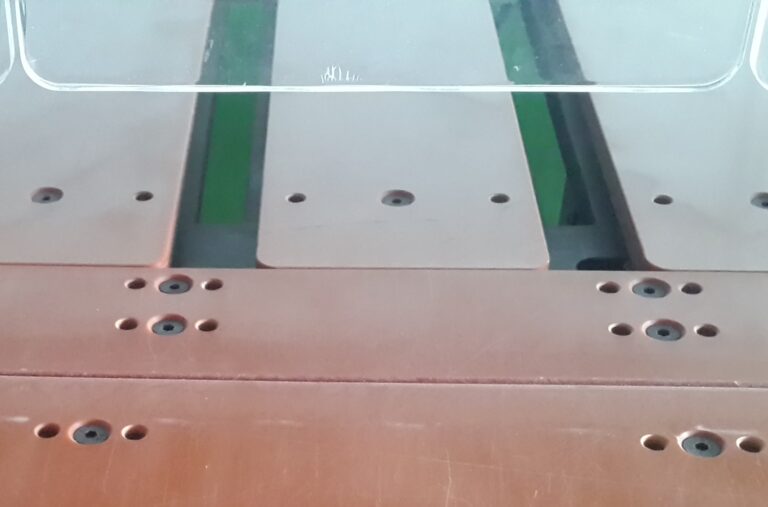

Fine control of the plate

► By adjusting plate bolt, it can control cross-joint precisely

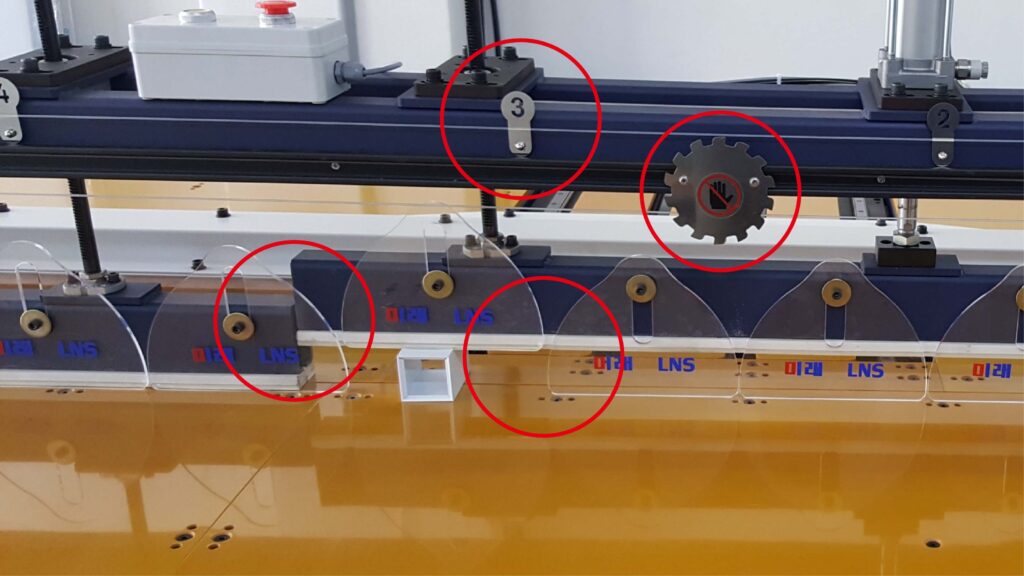

Double Splitting Auto Clamp

► Warm gear is applied to the clamp

► It is doubly split that it is unbiased when even cut the thick panels.

Saw Blade Position Indicator

► It is possible to check the saw blade’s position

► Depends on the materials and the size of work, saw blade’s position can be adjustable

► It can guarantee the safety and eliminate the error during work

Installation of Clamp Safety Cover

► By equipping a number of clamp type safety covers, in case of thick and small panel

cuttings, it will protect user’s hand.

Backward Point Indicator

► Backward point is indicated in numbers that letting users to know how much the main

axis will be backward after each cutting movement.

Size memory input method (optional)

► If you enter the desired cut size and quantity before starting work, the machine will automatically cut it.

► The jig automatically pushes the cut material and continues with the next cut.